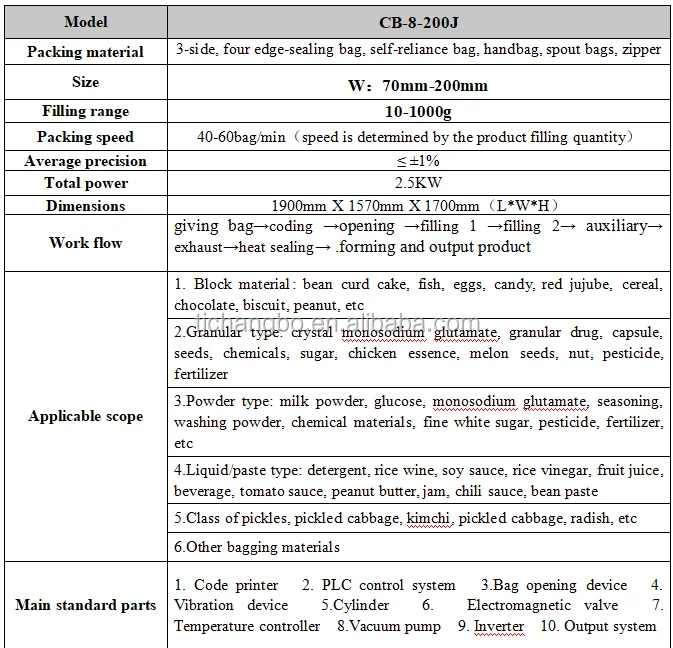

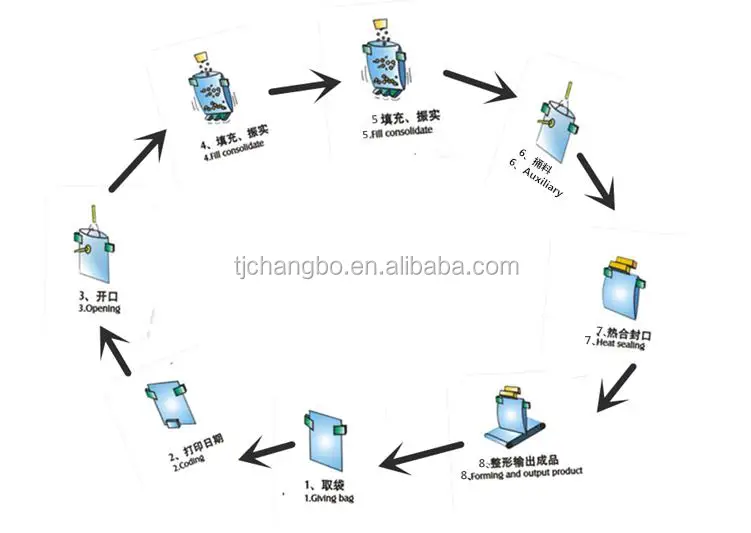

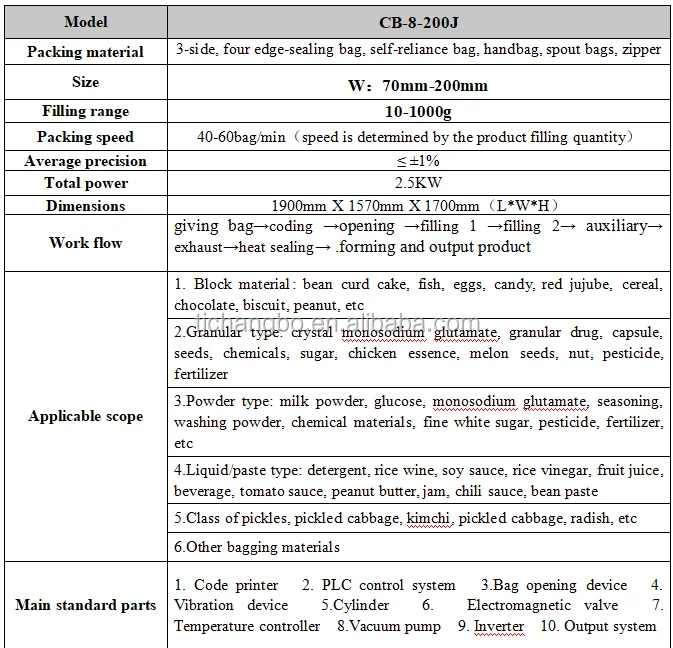

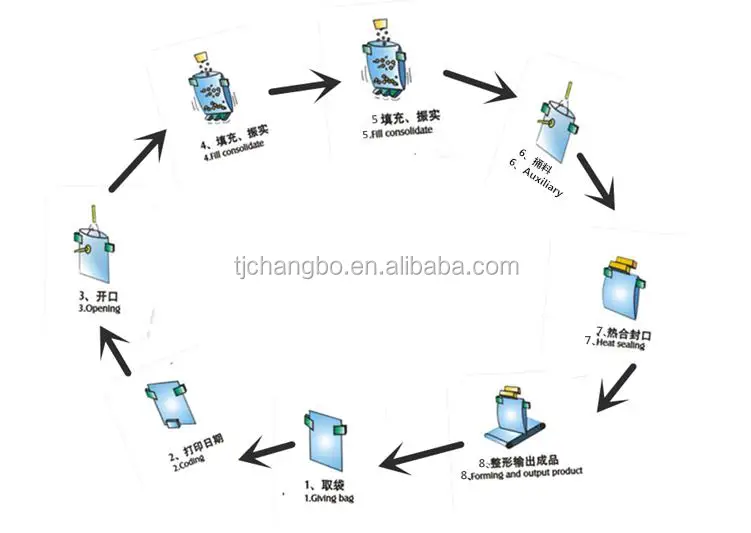

Bag given packaging machine replaces of manual packing type,which helps large enterprises,small and medium-sized enterprises reach to packaging automation,equipment mechanical grip will automatically take bag,print date,open the bag,to the metering device signal measurement and blanking,sealing,output.Main optional configuration for measuring material filling machine working platform,weight,scale,material hoist,vibrating feeder,finished goods transport hoisting machine,metal detection machine,etc.It adopts Japan's latest technology,under the total control system of PLC + POD,adopt mechanical structure,operation gradually replaced the operation of the pneumatic structure, to form a greater demands of the processing technology,easy operation,stable operation,maintenance,easy to clean,beautiful appearance.